Correlation between Additive Manufacturing Process Parameters and Microstructural Descriptors via Automatic Feature Engineering

Abstract

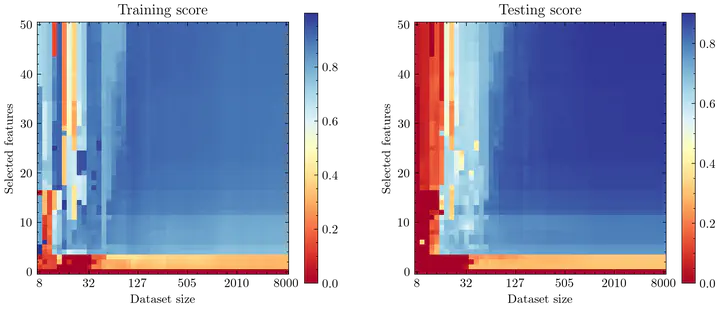

Additive Manufacturing AM of metals, the layer-by-layer manufacturing processes offer a lot of advantages over the traditional processes, however the lack of precise process-structures relationships present a major predicament into industrial scale implementation. In this paper we explore the use of automatic feature engineering coupled with machine learning to derive empirical relationships between processing parameters and microstructures. To illustrate this concept a kinetic Monte Carlo algorithm was used to generate the microstructures, this was done by varying 4 processing parameter and other 8 parameters related to the heat affected zone HAZ shape. The microstructures were than analyzed using image processing to extract key morphological properties, this include area size, aspect ratio (AR), … . Additional non-linear transformations and combination using arithmetic operators were then applied to the features dataset. The number features was reduced by feature importance analysis and by using coefficient magnitude. This allowed for the linear model to increase performance from R2 score of 0.4 to 0.902 for the area prediction and similar improvement for other morphological parameters.